Near-Infrared (NIR) Spectroscopy can revolutionize yogurt production by enabling real-time, accurate, and efficient fermentation process monitoring. By leveraging this technology, yogurt producers can achieve consistent product quality, minimize waste, and improve overall production efficiency.

Yogurt, or yoghurt – if you are British – has been a part of the human diet for millennia. History has it that it was likely discovered by accident when stored milk was observed to have curdled. Today, commercial yogurt production is controlled using specific cultures of Lactobacillus delbrueckii subsp. bulgaricus and Streptococcus thermophilus bacteria.

While there are many variations of yogurt, the production process typically follows the same basic steps. Milk is pasteurized by heating to around 85-90°C (185-194°F) for about 5 minutes to kill any harmful bacteria and denature proteins, helping to achieve a consistent yogurt texture. The milk is then cooled to around 42-45°C (107-113°F). Live yogurt cultures are added to the milk, and these bacteria ferment lactose (milk sugar) into lactic acid, which thickens the milk and gives yogurt its characteristic tangy flavor. Fermentation occurs over 4-12 hours, depending on the cultures used and the desired product tartness.

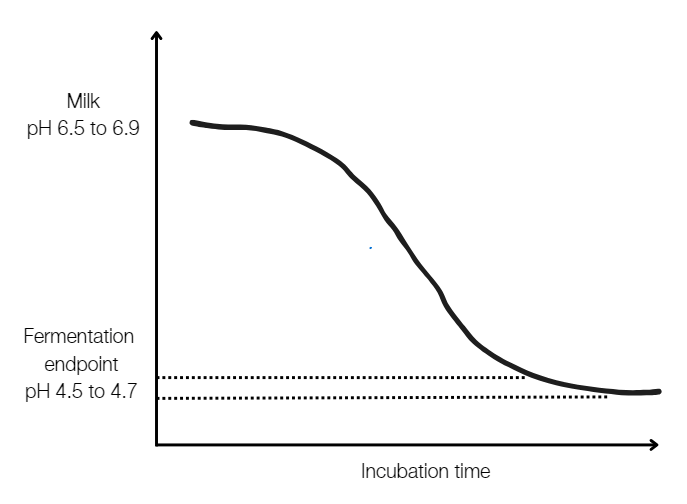

During fermentation, lactic acid bacteria convert lactose into lactic acid, lowering the pH to approximately 4.5 to 4.7 (Figure 1). The fermentation process is deemed complete when the pH stabilizes within this range. Periodic checks are required to ensure the yogurt has the desired consistency and flavor. At the fermentation end-point yogurt is cooled to around 4°C (39°F) to stop the fermentation process and stabilize the product.

Determining the endpoint of fermentation is a critical step because it can significantly impact the final product’s texture, flavor, and overall quality. Traditional methods often rely on time-based estimations or manual sampling, which can be inefficient and imprecise. For example, visual and taste assessments are subjective and inconsistent, while other methods like brix, microbial activity, or pH measurements can be labor-intensive and time-consuming.

Near-infrared (NIR) spectroscopy offers a modern solution to these challenges. This non-destructive analytical technique leverages the absorption or reflection of NIR light by a sample to obtain information about its chemical composition.

An experiment conducted at the BUCHI lab in New Castle, Delaware, demonstrated the effectiveness of using NIR to measure pH. Samples with pH levels ranging from 6.68 to 2.88 were created by gradually adding lactic acid to equal volumes of whole milk. To ensure an even distribution of the lactic acid, the samples were stirred, and pH measurements were taken within one minute. A portable pH meter (Model A1311, Apera Instruments, Columbus, OH, USA) was used to measure the pH by mixing the sample and inserting the probe, without any additional preparation. Next, the NIR spectrum of each sample was collected using the BUCHI NIR-Online sensor (Figure 2) in a lab setup.

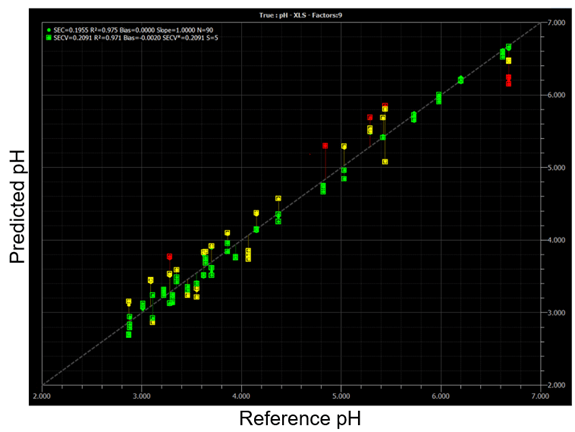

A partial least squares (PLS) regression model was developed to create an NIR model for pH. The calibration showed good linearity during cross-validation (R2cv= 0.971) and a low standard error of cross-validation (secv = 0.21), supporting the use of NIR to accurately monitor decreasing product pH during fermentation (Figure 3).

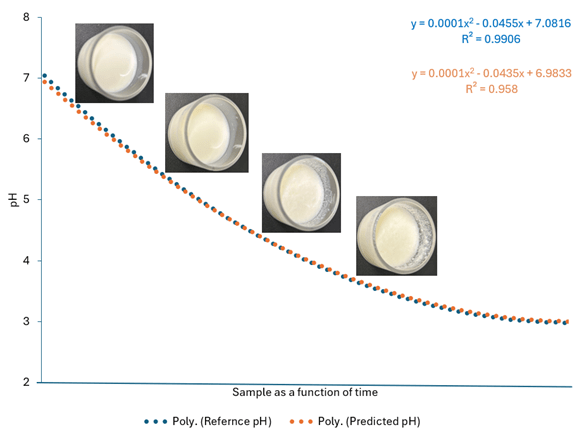

Replotting and trending the calibration data recreates the pH profile throughout the lactic acid fermentation of milk into yogurt (Figure 4). The reference pH trend closely follows the predicted pH trend.

Traditional methods for endpoint determination often involve routine sampling for laboratory analysis. This process can be slow, and lag times between sampling and analytical results may not accurately reflect the current state of the fermentation process. In contrast, an in-process NIR analyzer can provide continuous real-time data, enabling producers to monitor fermentation without frequent sampling. NIR can also predict multiple properties simultaneously, such as lactose, lactic acid, and protein, giving a more comprehensive view of the product’s quality.

The BUCHI NIR-Online software displays live data trends for all calibrated properties (Figure 5), providing actionable data that can be used to stop the fermentation process at the optimal moment, ensuring consistent product quality. Real-time monitoring also provides plant managers with opportunities to adjust the fermentation process if deviations are detected. This proactive approach improves quality control and ensures that the yogurt meets the desired standards for texture, flavor, and acidity.

In summary, in-process NIR is a promising tool to enhance production efficiency by reducing manual sampling and laboratory analysis, facilitating faster decision-making, and minimizing the risk of over- or under-fermentation. BUCHI offers integration solutions for NIR-Online into fermentation tanks, along with installation, training, and ongoing support to maintain sensor accuracy and performance.

For more information on BUCHI NIR-Online process analyzers, visit the NIR-Online product page. For project inquiries, contact us via your local BUCHI Account Manager or use this webform.

Leave a comment