Hello, it’s Dr. Rukundo!

For our first blog of 2026, we’re turning our attention to something both environmentally crucial and full of untapped potential: the recycling of organic waste. You’ve probably heard the saying, “One man’s trash is another man’s treasure.” When it comes to food waste, that statement holds truer than ever.

Across the entire food supply chain, the “leaky food pipeline” highlights how much food is lost from the moment it is harvested to the moment it reaches our tables. Losses and waste occur due to poor handling, storage issues, transportation challenges, and even consumer behavior. Think for a moment about grocery stores that discard meat cuts simply because their color has changed slightly. The food may still be safe, but its visual appeal is compromised, and so it ends up in trash. What we really lose, in the end, is unused energy – energy that could have been put to work rather than wasted. Through thoughtful recycling technologies, this energy can be recovered and repurposed.

How Anaerobic Digestion Turns Waste into Energy

One of the most effective tools for recovering energy from organic waste is anaerobic digestion, carried out in a system known as a biodigester. A bio-digester is a system that breaks down organic waste (like food scraps, manure, or agricultural residue) using anaerobic digestion — a natural process where microorganisms decompose organic material in the absence of oxygen. This converts organic waste into two main useful byproducts:

Biogas (primarily methane + CO₂): can be used for cooking, heating, electricity generation, or even fuel for vehicles.

Digestate (a nutrient-rich slurry): used as an organic fertilizer for crops.

In addition to food waste, anaerobic digesters can process a wide range of organic inputs, including agricultural waste such as animal manure, crop residues, and silage; industrial organic waste like dairy by-products, brewery waste, and slaughterhouse residues; as well as sewage sludge from municipal wastewater treatment plants. Energy crops such as maize or grass silage are also sometimes used, particularly in large-scale systems. These feedstocks provide the necessary carbon and nitrogen for microbial activity during digestion.

A typical biodigester is composed of several interconnected components that keep the system functioning efficiently. Incoming organic materials enter through an inlet and move into the digestion chamber, where oxygen-free conditions are carefully maintained so bacteria can carry out anaerobic breakdown. As the digestion process occurs, biogas is released and captured through a gas outlet, while the remaining digestate exits through a slurry outlet to be used elsewhere.

The Need for Efficient Monitoring

To keep this complex system running smoothly, regular biochemical testing is necessary. Operators need information about the incoming material and the digestion process to make decisions regarding feeding rates, blending of inputs, and overall efficiency. Traditionally, tests such as Total Solids, Volatile Solids, Total Kjeldahl Nitrogen, COD, BOD, phosphorus, pH, volatile fatty acids, ammonia, and alkalinity are measured using wet chemistry methods. While effective, these techniques are often time-consuming, labor-intensive, and reliant on chemicals that can pose safety risks. They also generally require specialized equipment and, in some cases, third-party laboratory analysis. This means delays in decision-making and increased operational costs. To maintain optimal digester performance, feedstocks are frequently diluted to achieve the right solids content and nutrient balance, while contaminants such as plastics or chemicals must be removed before digestion begins.

This is where Near infrared (NIR) spectroscopy offers a compelling and modern alternative. NIR works on the principle of light interacting with material and producing a spectrum that reflects its composition. By developing calibrations that relate these spectra to specific chemical and physical properties, operators can monitor routine samples in real time. This capability dramatically speeds up the decision-making process. Instead of waiting hours or days for analytical results, plant operators can assess material characteristics in seconds or minutes and take immediate action when needed.

Real-Time Performance Insights With NIR-Online

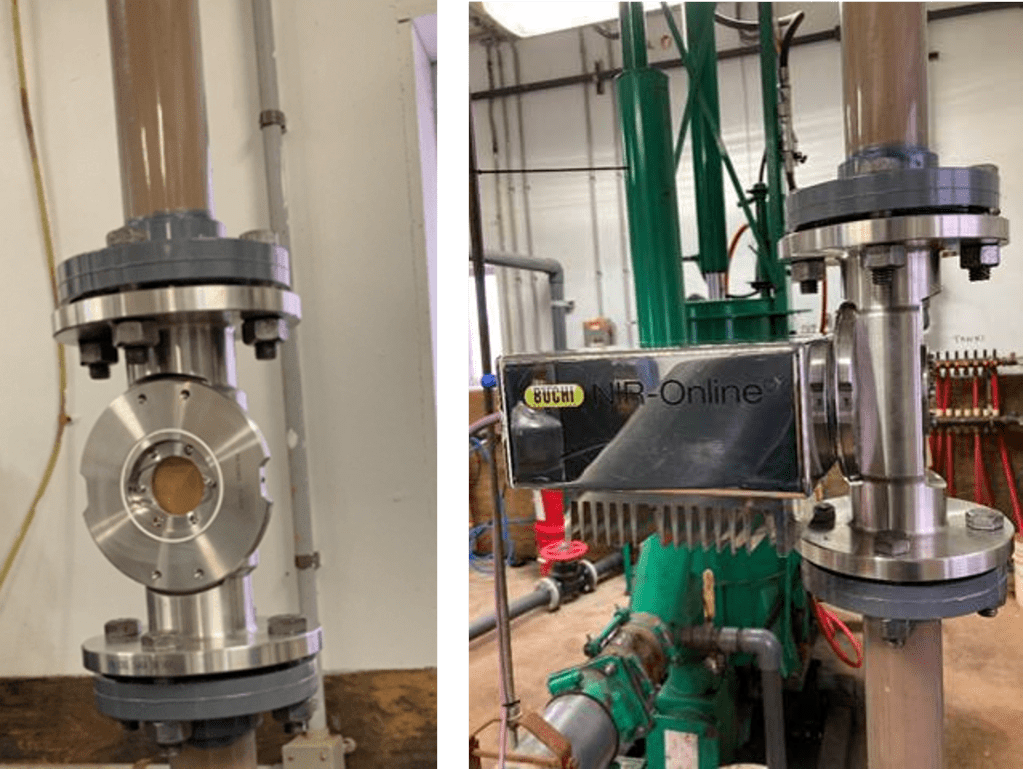

Technologies such as BUCHI’s NIR-Online system exemplify the advantages of real-time monitoring. When installed directly on a pipe carrying material into the digester, the system continuously analyzes the feedstock and overall process conditions. This provides operators with instant insight into how the digester is performing and whether any disturbances are developing. The ability to detect changes as they occur improves operational efficiency and helps mitigate risks related to fluctuating feedstock quality.

The NIR-Online can be attached to a pipe carrying material that’s fed into the digester

Real-time monitoring becomes especially valuable during the ramp-up phase, when digesters are gradually fed increasing volumes of new materials. This period is sensitive, and disruptions can occur quickly. For example, adding large quantities of corn syrup or offal may lead to foaming inside the digester. Such events can compromise performance, reduce gas production, and even cause system shutdowns if not addressed promptly. With NIR-Online in place, any change in the matrix composition is identified immediately. Operators can then adjust the feed or blend materials differently to prevent downstream issues.

Consider a situation in which several predicted variables—such as COD, sodium, and aluminum—begin moving outside their normal operational range. This would signal that immediate intervention is needed. One practical corrective action is the introduction of activated carbon, which can take the form of crushed coal or charcoal. These materials are often readily available and help stabilize the system, preventing foaming and allowing biogas and electricity production to continue uninterrupted. This type of early-warning response is only possible with real-time data.

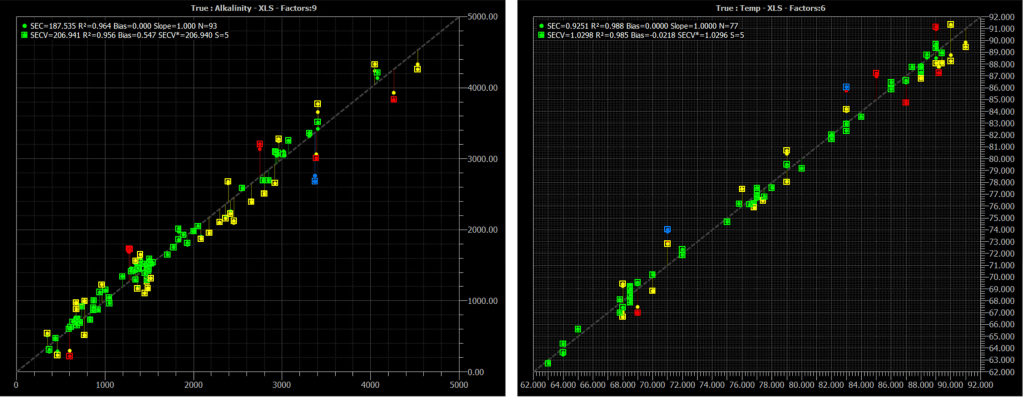

Examples of calibrations used to predict two properties in an incoming material mix for anaerobic digestion

The predictive power of NIR-Online is supported by carefully developed calibrations capable of estimating properties of incoming material mixtures used for anaerobic digestion. By providing this continuous stream of information, NIR-Online becomes a valuable tool for risk mitigation. Operators can run their systems more confidently, more efficiently, and at a higher performance level, resulting in increased gas output and improved financial returns.

Interested in Real-Time Monitoring? Let’s Talk

If you are interested in taking advantage of real-time monitoring at different stages of your digestion process, we encourage you to reach out to us through our webform. We would be delighted to discuss your specific application and support you throughout the implementation journey.

Leave a comment